Mercury Intrusion Porosimetry (MIP)

Mercury intrusion porosimetry (MIP) is used to evaluate porosity, pore size distribution, and pore volume of various solid and powder materials.

- Description

|

Testing Method |

Mercury Intrusion Porosimetry (MIP) |

|

Description |

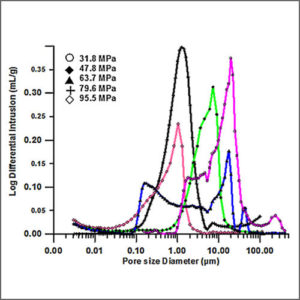

Mercury intrusion porosimetry (MIP) is used to evaluate porosity, pore size distribution, and pore volume of various solid and powder materials. The technique involves the intrusion of a non-wetting liquid (often mercury) at high pressure into a material through the use of an instrument, known as a porosimeter. The instrument employs a pressurized chamber to force mercury to intrude into the voids in a porous substrate. As pressure is applied, mercury fills the larger pores first. As pressure increases, the filling proceeds to smaller and smaller pores. Both the inter-particle pores (between the individual particles) and the intra-particle pores (within the particle itself) can be characterized using this technique.

The pore size can be determined based on the external pressure needed to force the liquid into a pore against the opposing force of the liquid’s surface tension. Since the technique is usually performed within a vacuum, the initial gas pressure is zero. The contact angle of mercury with most solids is between 135° and 142°, so an average of 140° can be taken without much error. The surface tension of mercury at 20 °C under vacuum is 480 mN/m. As pressure increases, so does the cumulative pore volume. From the cumulative pore volume, one can find the pressure and pore diameter where 50% of the total volume has been added to give the median pore diameter. |

|

More Information |

Wikipedia: Porosimetry |